Projects

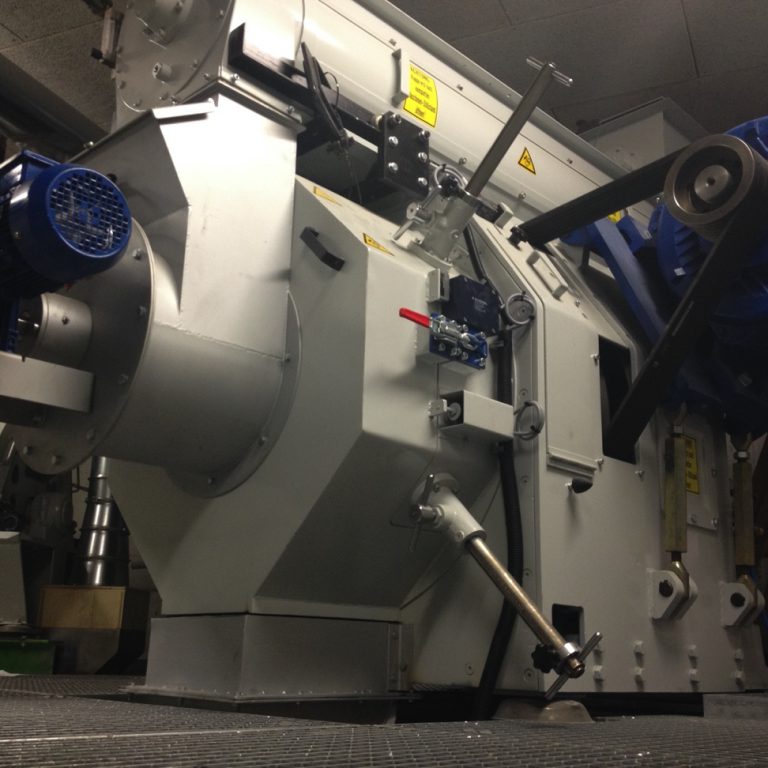

APT specializes in consulting on pelletizing plant projects, with more than 20 years of experience in the industry. We help you from the project to the start-up, modernizing or expanding the technology of the Pellet lines to the latest state of the art. We help you determine the capital investment as well as the necessary spare parts for a continuous production. Learn more from our projects below.

Consulting

Consultant for the customer, in order to configure his Plant in accordance to mentioned features and reaching desired quality and quantity.

Machines

We advise you on the selection of the best machinery and brands for your specific case

Spare Parts

We are beside you not only until the Plant is commissioned, because so called fine tuning and subsequent Service is an absolute must for any Pellet Plant.

Our Projects

Our Projects

Germany

Finland

France

Indonesia

Russia

Vietnam

Austria

Portugal

2022

Indonesia

Task 4 – 5 to/h Wood pellets out of dry and wet wood with different sizes and shapes, Soft- and Hardwood – Consultancy in configuration of plant and election of machines and vendors

From 2021

Germany

Torgau

Task – Consultancy for improvement and renewing of an existing pelletizing plant, project managing for execution of each step

2022

Germany

Niedernwöhren

Task 4,5 to/h treatment of straw bales and size reduction ready for Pelletizing

Process Steps: straw bale breaking, fine grinding, transport to storage

2021

Germany

Werbach

Task 3 to/h Speltpellets out of dry Spelt husks

Process Steps: humidity regulation, pelletizing, cooling and sieving of products

2013

France

Biblisheim

Task – 2 to/h Woodpellets out of dry Sawdust and wet Wood Chips from Recycling process. Realized without drying, but by proper mixing dry and wet raw materials in an appropriate ratio, Soft- and Hardwood.

Process steps: double step grinding, mixing area, moisture regulation, pelletizing, cooling and sieving of product, bagging in 15 kg bags